Nikon Constructs New Manufacturing Facility to Meet ArF Demand

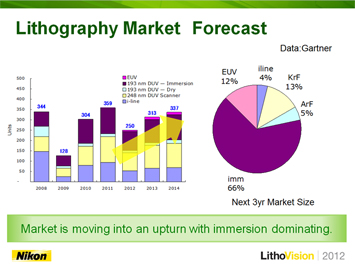

Next generation lithography techniques continue to evolve, but IC makers need solutions today that will keep them on their aggressive technology roadmaps. As a result, extension of ArF lithography plays a vital role in maintaining production timelines. At the recent LithoVision technical symposium, Toshikazu Umatate, Nikon Corporation General Manager of Sales Headquarters and Company Vice President, reported that Gartner Dataquest data from December, 2011 indicates that the lithography equipment market is moving into an upturn, with immersion systems dominating the litho tool segment over the next several years.

-

Click image to enlarge.

-

Click image to enlarge.

Figure 1. Umatate referenced December, 2011 Gartner data indicating that immersion systems will dominate the litho tool segment over the next several years (left image). To satisfy ArF scanner demand, Nikon constructed an additional manufacturing facility in Kumagaya.

To meet these challenges, Nikon developed two new 193 nm scanners—the latest evolutions of the proven Streamlign platform, which has already been adopted in leading-edge facilities worldwide. The NSR-S621D immersion and NSR-S320F dry ArF scanners are currently being shipped to customers globally to satisfy the rigorous requirements for imaging, overlay accuracy, and ultra-high productivity that are essential for cost-effective 22 nm applications and beyond. In light of the heightened demand for ArF extension solutions, Nikon constructed an additional manufacturing facility in Kumagaya, Japan to boost production capacity for dry and immersion ArF scanners. Umatate reported that the facility has been completed and is ready for high volume manufacturing of these critical ArF lithography systems.