LithoVision Presentations Highlight EUV HVM Challenges and

Nikon Advancements

At the Nikon symposium held earlier this year, Katsuhiko Murakami, Nikon Development Group Leader, reported on some of the EUVL challenges for high volume manufacturing (HVM) and discussed the latest Nikon progress, showing data from the Nikon beta tool, EUV1. Murakami began his presentation by showing expected reduction of the k1 factor as half-pitch (hp) shrinks, using DRAM as an example. He highlighted that, due to challenges in the EUV infrastructure, Nikon has developed comprehensive solutions to print at ~20 nm hp using ArF immersion extension, while continuing development of EUVL for possible use at 16 nm and beyond. Murakami explained that an EUV system with numerical aperture (NA) = 0.32-0.35 would only deliver sufficient k1 to satisfy requirements for 16 nm hp printing, making it a single generation solution. He contrasted this with an EUV system having NA > 0.4 and said that this would also cover the 11 nm hp node, making it multigenerational and therefore a more viable solution.

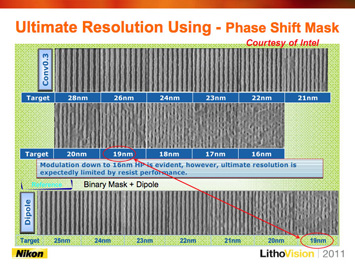

Murakami then showed EUV1 progress, beginning with flare, showing that the #2 projection optics (PO) of EUV1 have achieved Kirk flare values of 8.5% (2 µm Kirk pattern in bright field), close to a 50% reduction compared to the #1 PO. He also discussed improvements in mirror-polishing technology and reported that further reductions in mid- and high-spatial frequency roughness had reduced flare and enhanced reflectivity. Murakami said that Nikon optics fabrication technology satisfies EUV HVM requirements, showing EUV1 conventional and dipole resolution (courtesy of Intel Corporation) achieved using a phase shift mask, with pattern modulation below 19 nm hp evident. The ultimate resolution was, as expected, limited by resist performance not by the optics.

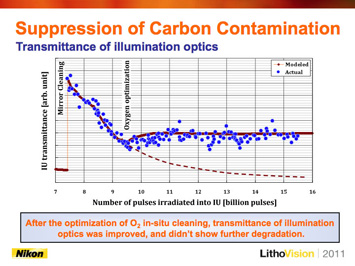

Figure 1. EUV1 resolution (courtesy of Intel Corporation) achieved using a phase shift mask, with pattern modulation below 19 nm hp evident (left image). O2 in-situ cleaning optimization halted degradation of EUV light intensity at the reticle.

Murakami then discussed mitigation of carbon contamination, an important requirement for HVM optics. He explained that contamination/cleaning modeling was established using data obtained from experiments at the SAGA LS synchrotron facility. In the study, optimization of O2 in-situ cleaning halted degradation of EUV light intensity at the reticle, holding transmittance of the illumination optics steady. Moving then to discuss progress towards HVM exposure tools, Murakami showed imaging simulations comparing conventional and dipole illumination. He explained that using NA > 0.3 with conventional illumination would not provide a sufficient process window for 16 nm hp printing; off-axis illumination is required. The simulations also verified his earlier statements that NA ≥ 0.4 with off-axis illumination will be required for 11 nm hp printing. Murakami provided further details on NA > 0.4 optics design and reported that Nikon is studying three projection optics designs: 6-mirror, 6-mirror with central obscuration (CO), and 8-mirror. He noted that while a design with CO enables the optical designer to increase NA, its impact on imaging must also be considered. For instance, CO designs can show significantly reduced contrast when printing with dipole illumination at certain pitches. Murakami then showed a comparison of the various designs (summarized below) and commented that Nikon investigation of the optimal high-NA PO design continues.

NA > 0.4 Optics Design Comparison

| 6-mirror system | Relatively large wavefront error |

|---|---|

| 6-mirror system with CO | Low wavefront error, high transmittance, impact of central obscuration (CO) |

| 8-mirror system | Low wavefront error, low transmittance, need high-power EUV source |

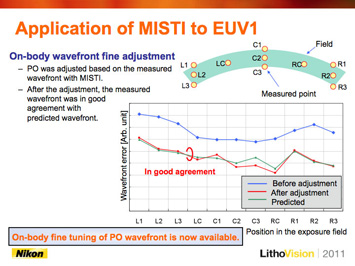

As readers know, accurate wavefront metrology of the projection optics is necessary in modern tools. This is particularly challenging at EUV wavelengths. Looking next at metrology, Murakami reported that a new actinic wavefront metrology scheme using the Multi-incoherent Source Talbot Interferometer (MISTI) has been developed. Murakami went on to explain this method could be applied to on-body wavefront metrology of EUV exposure tools, and reported that the EUV1 PO had been adjusted based on the wavefront measured with MISTI. He said that, following adjustment, the measured wavefront agreed well with the predicted wavefront, and reported that on-body fine tuning of the PO wavefront is now available.

Murakami next commented briefly on consideration of a shorter EUV wavelength, (6.7 nm) and reported that while advantageous for resolution and depth of focus, it presents several key challenges with the multilayer coatings, EUV source, and flare.

Murakami concluded his in-depth EUV update by reminding the audience that the target of EUVL is 16-11 nm hp node, with an NA > 0.4 to enable multiple generation capabilities. He reiterated excellent EUV1 progress in flare, low-hp printing, and carbon contamination, and highlighted the recent accomplishments in HVM system optical design (NA > 0.4) and on-body wavefront control.

Figure 2. The EUV1 PO has been successfully adjusted based on the wavefront measured with MISTI (left image). Murakami reiterated that the target of EUVL is 16-11 nm hp node and highlighted the progress toward HVM exposure tools.

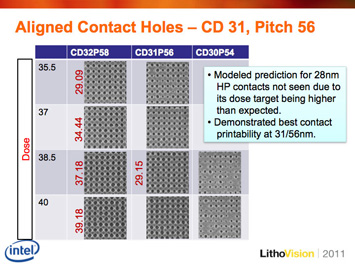

Later in the evening at the LithoVision poster session, Dr. Yashesh Shroff, Senior Engineer from Intel Corporation provided further details on the Nikon EUV1 tool evaluation, and reported that the final EUV1 evaluation was completed. He commented that the tool performed well throughout the test with good CD stability < 0.5 nm/100 shots CD drift – with no discernable focus drift. Further, he noted significant improvement in dose stability as compared to earlier studies. Shroff also reported that EUV1 static slit Kirk-flare measurements showed center slit flare of 7.5 ~ 9.4% using the 2 µm line feature, and highlighted the EUV1 22 nm hp ultimate resolution and pattern modulation down to 19 nm. He showed that 31 nm contacts had been successfully printed as well.

Figure 3. Shroff showed that 31 nm contacts have successfully printed with the EUV1 (left image). He reported that the final EUV1 evaluation was completed with the tool performing well throughout the tests.