A Simple Approach to Litho-Litho-Etch Processing Utilizing Novel Positive Tone Photoresists

Double patterning has become a strong candidate for 32 nm half-pitch lithography and beyond, with Litho-Etch-Litho-Etch (LELE) and Self-Align Double Patterning (SADP) processes being the main areas of investigation for critical pitch patterning. However, both of these processes introduce significant cost challenges, and the SADP process is further limited to line array applications only. Therefore, an alternative Litho-Litho-Etch (LLE) process is necessary in order to simplify the double patterning process and reduce cost of ownership for IC manufacturers. The ideal "simple" LLE process would not require any additional chemicals or further processing. To achieve these objectives, TOK initiated development of an uncomplicated LLE process utilizing a positive-positive photoresist approach.

A Freezing-Free Litho-Litho-Etch process

As reported recently[1] , resist freezing by chemical or processing approaches has been proposed for Litho-Litho-Etch solutions. However, such freezing processes require additional chemicals or increased steps to prevent unwanted mixing or reactivation in the first layer film at the second lithography step. To simplify LLE, TOK instead focused on developing a Freezing-Free process that doesn't necessitate additional chemicals or processing.

Litho-Litho-Etch consists of a resist-on-resist process, and in order to achieve a successful LLE process without freezing, it is necessary to take care of two vital concerns. One is the risk of mixing between the first and second photoresists, and the other is the potential for reactivation of the first photoresist at the second exposure. To eliminate the risk of mixing, several process changes are necessary, including the introduction of a new solvent to the second photoresist that is unable to dissolve the first photoresist film, as well as utilization of a newly designed polymer that can be dissolved in the new solvent of the second photoresist. In addition, a hardbake is needed after the first development step to remove any remaining solvent in the first photoresist pattern. This is a critical step because if the solvent was allowed to remain, the first photoresist pattern could be dissolved even with the new type of solvent, as a result of the mixing effect.

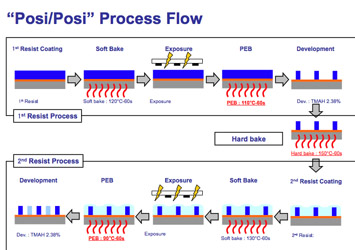

To address the reactivation concern in order to maintain the first pattern, it is also necessary to ensure there is a sufficient delta between the activation energy of the first photoresist and the post expose bake (PEB) temperature of the second photoresist. This is because although the high activation energy first photoresist will easily react with the generated acid at a high PEB temperature, it is far less likely to react at a low PEB temperature. When the PEB of the second lithography step is set to a low temperature, (90ºC or below) a high activation energy-type first photoresist pattern can be maintained at its initial critical dimensions (CD). TOK has developed an innovative Freezing-Free Litho-Litho-Etch process that incorporates all of these elements. The process flow of the TOK Freezing-Free LLE process is shown in figure 1. This solution is called a "Posi/Posi" process as it utilizes two different positive tone photoresists for patterning.

Figure 1. Freezing-Free LLE "Posi/Posi" Process.

Double patterning capability

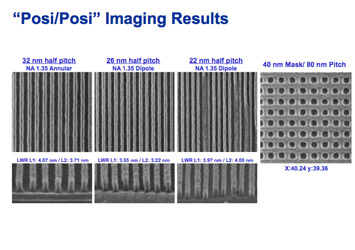

Having shown that the "Posi/Posi" process is a viable candidate for double patterning, it is also necessary to verify that this process is sufficiently mature to apply to lithography in manufacturing. Typically, dual-line patterning and cross-line patterning are evaluated for LLE processes. In the case of dual-line patterning, resolution has been achieved down to the 26 nm half pitch and 22 nm separation (with some pattern collapse observed) using the Freezing-Free LLE "Posi/Posi" process as shown in figure 2. Furthermore, the etching bias at poly-Si etch was around 1 nm, with only a very small difference between the first and second pattern etching bias. When considering cross-line patterning used to make contact hole (CH) arrays, the TOK "Posi/Posi" process can easily print 40 nm contacts on an 80 nm pitch. This cross-line patterning method is actually able to achieve smaller contact hole sizes compared to single photoresist lithography, and the CD uniformity of the contact holes is also much better.

Figure 2. Imaging results of Freezing-Free LLE "Posi/Posi" Process.

Although LELE and SADP processes have been the primary areas of investigation for DP techniques, both lithography methods present cost challenges and SADP also has limited applications. Therefore, TOK has focused on development of a simple Litho-Litho-Etch process to reduce process cost and complexity for customers. Although Freezing-Free lithography can present challenges with regard to mixing and reactivation between the photoresist layers, TOK has incorporated a variety of process innovations to eliminate these issues. The TOK Freezing-Free LLE "Posi/Posi" process is fully capable of printing the necessary critical features for DP applications, and provides a cost effective alternative to LELE processes, making it a viable lithography solution for the 32 nm half-pitch node and beyond.

Reference

[1] Maenhoudt M. et al., "Alternative process schemes for double patterning that eliminate the intermediate etch step" Proc. SPIE 6924 (2008) 69240P.

Tsuyoshi Nakamura

Senior Engineer, Research & Development Division

TOK Co., Ltd.

t-nakamura@tok.co.jp